I'M Satyapalsinh Gohil

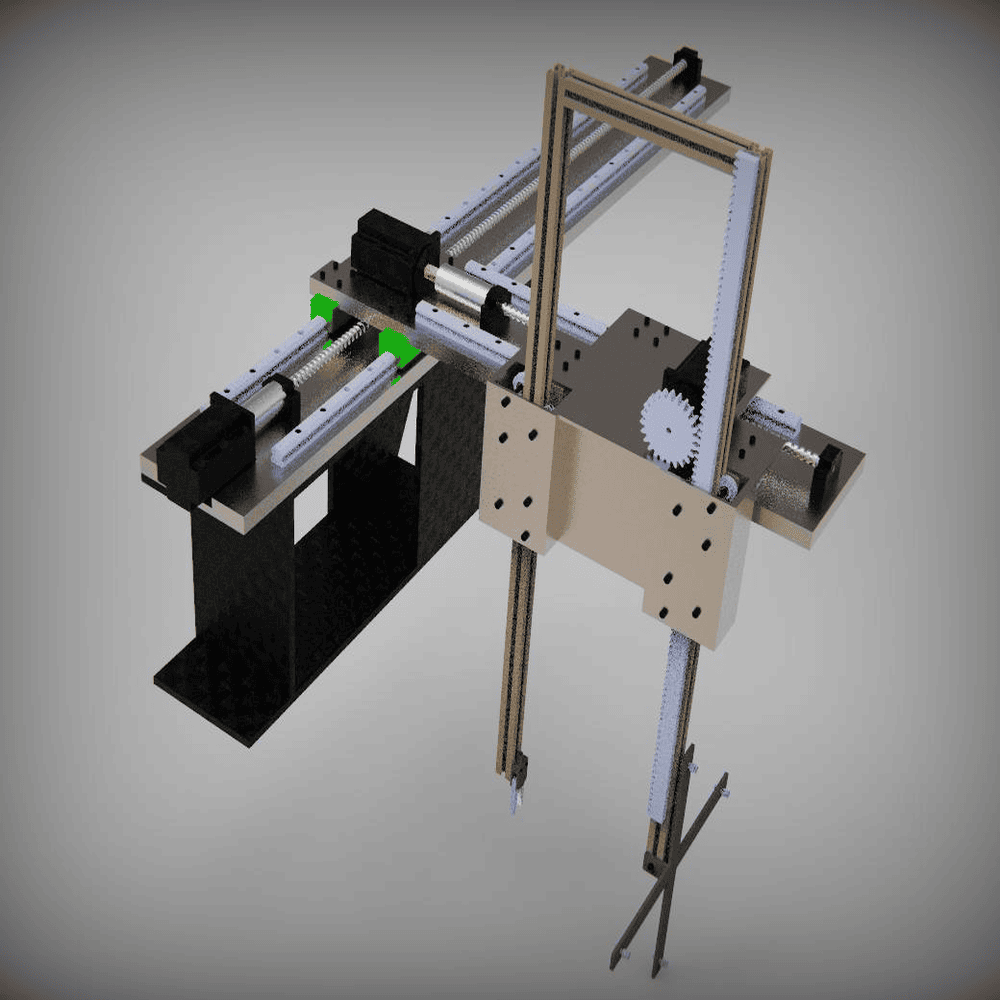

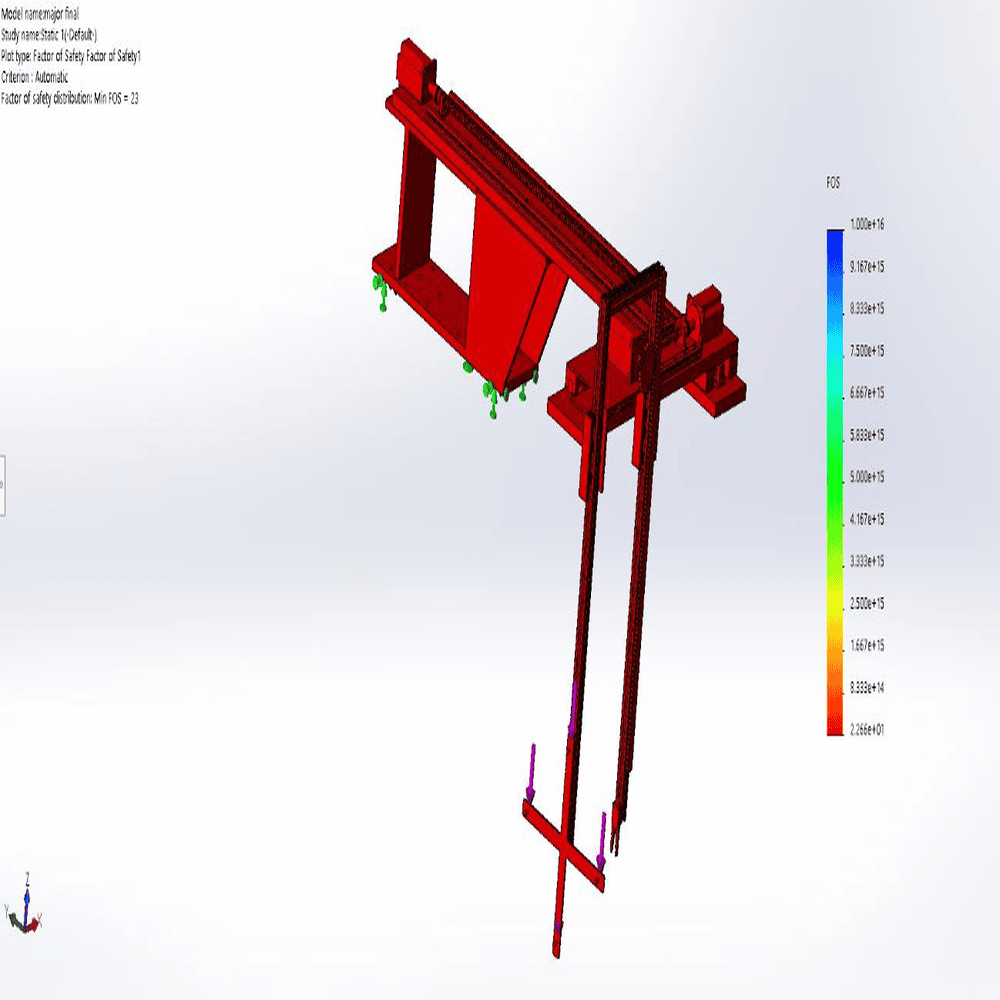

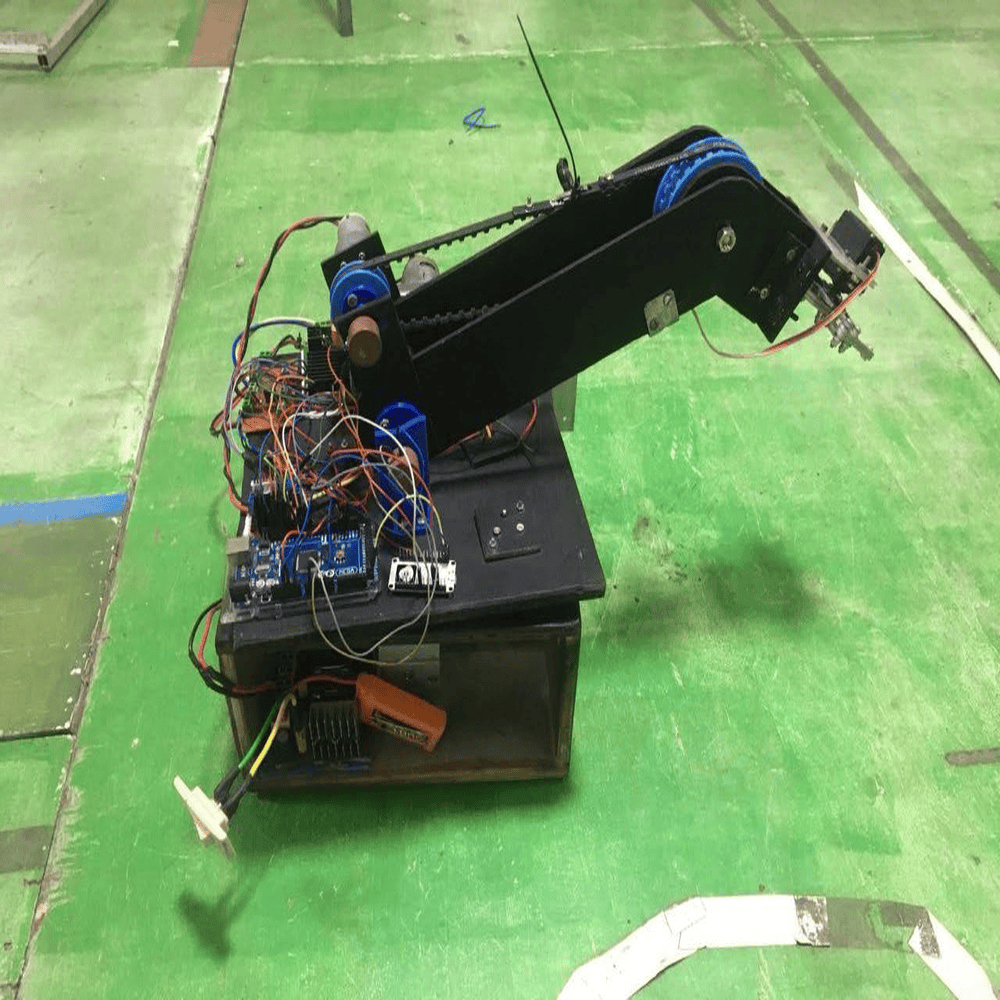

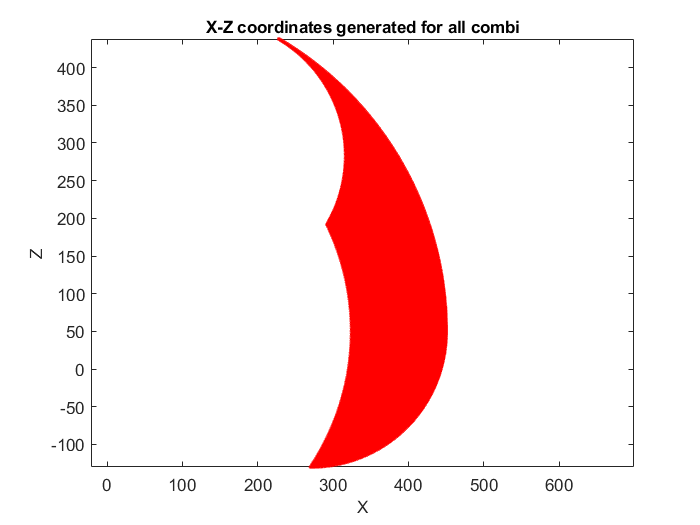

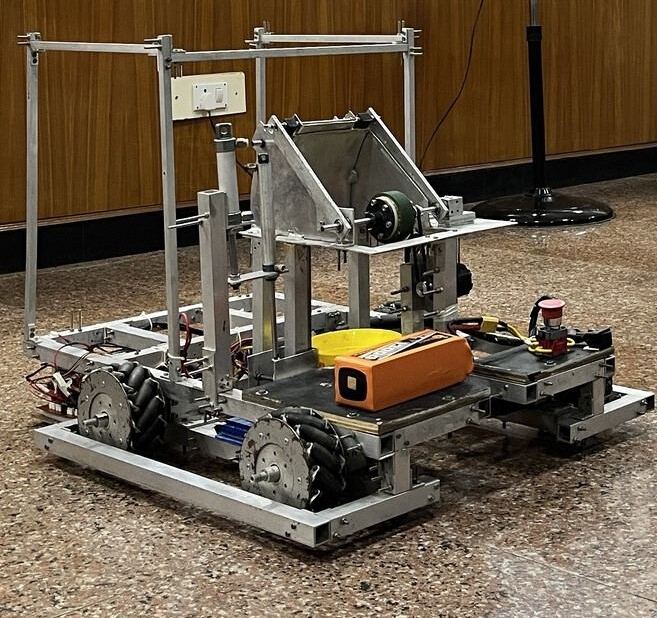

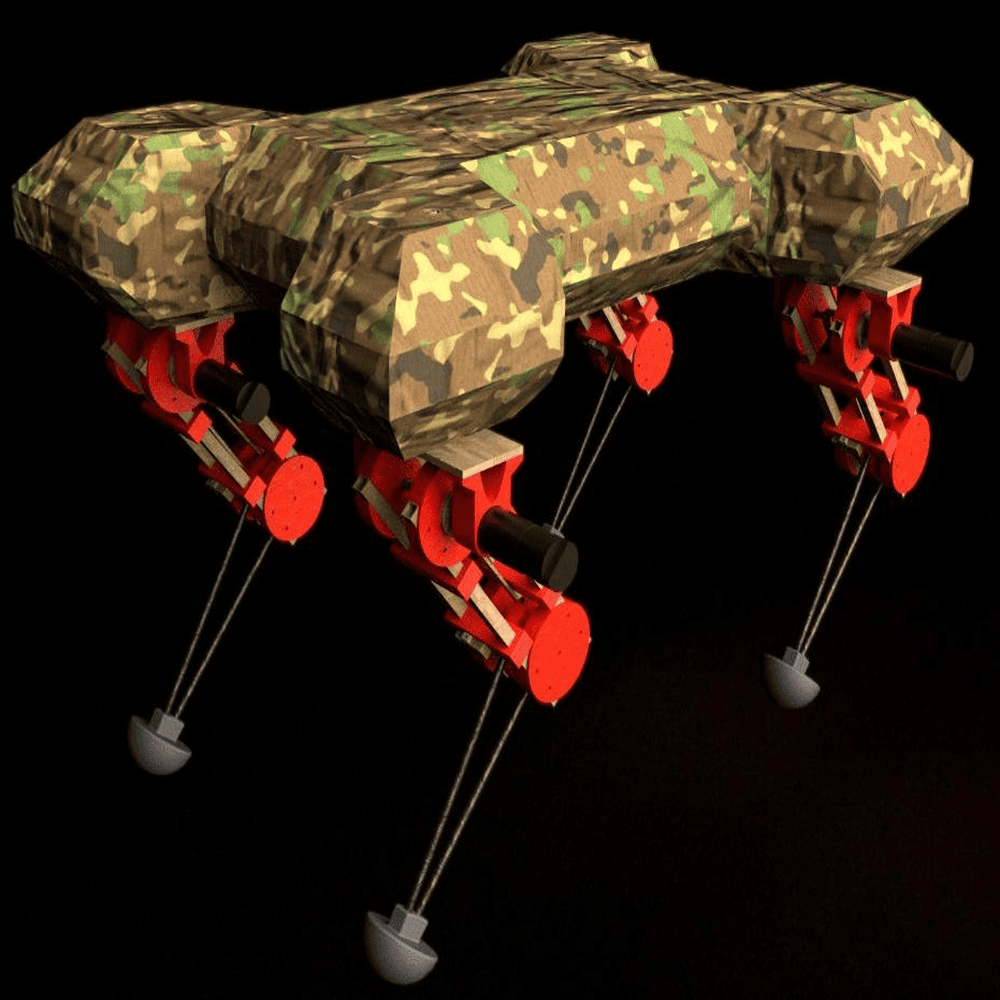

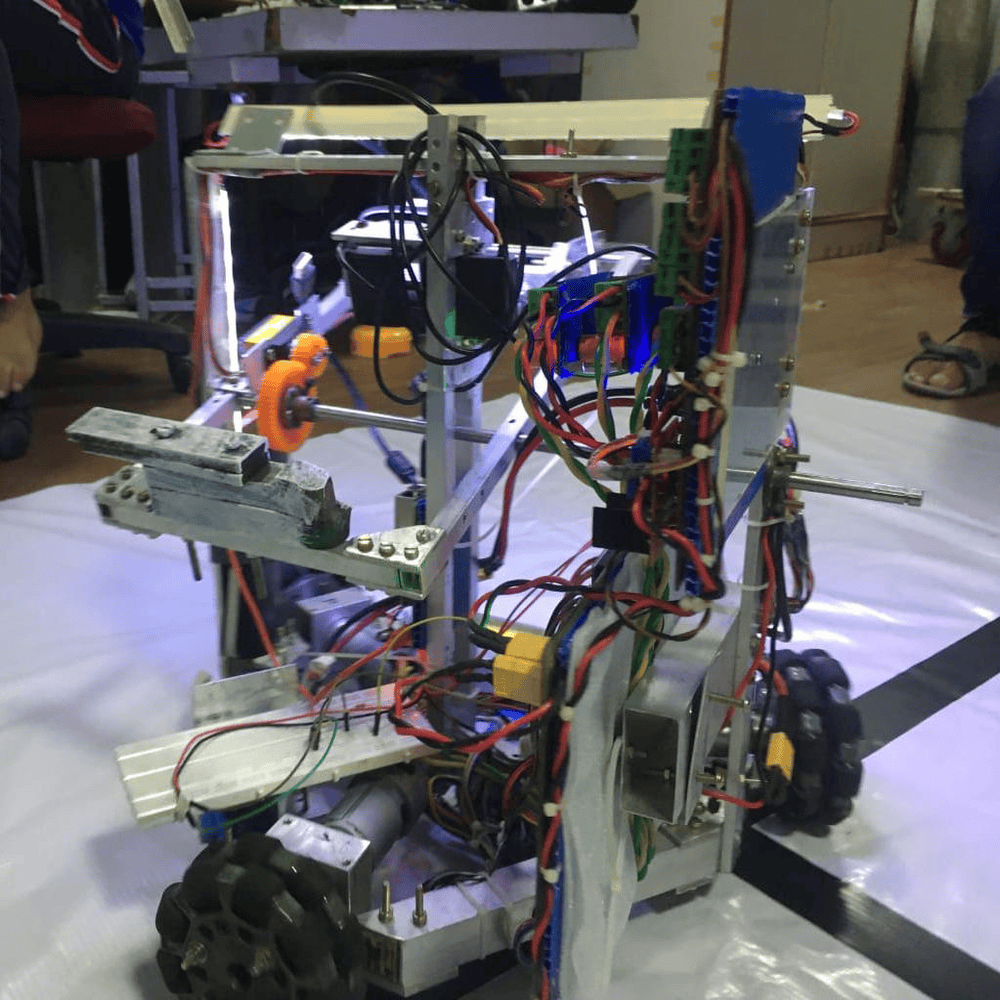

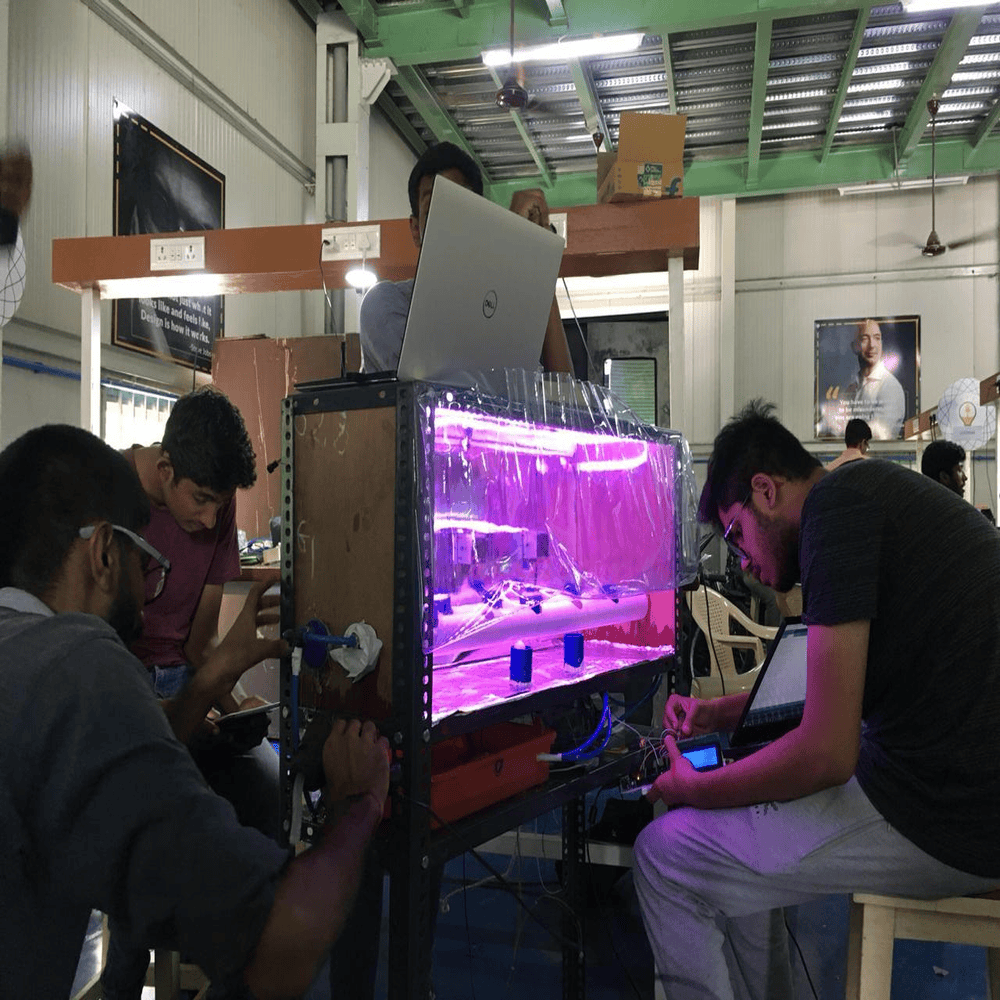

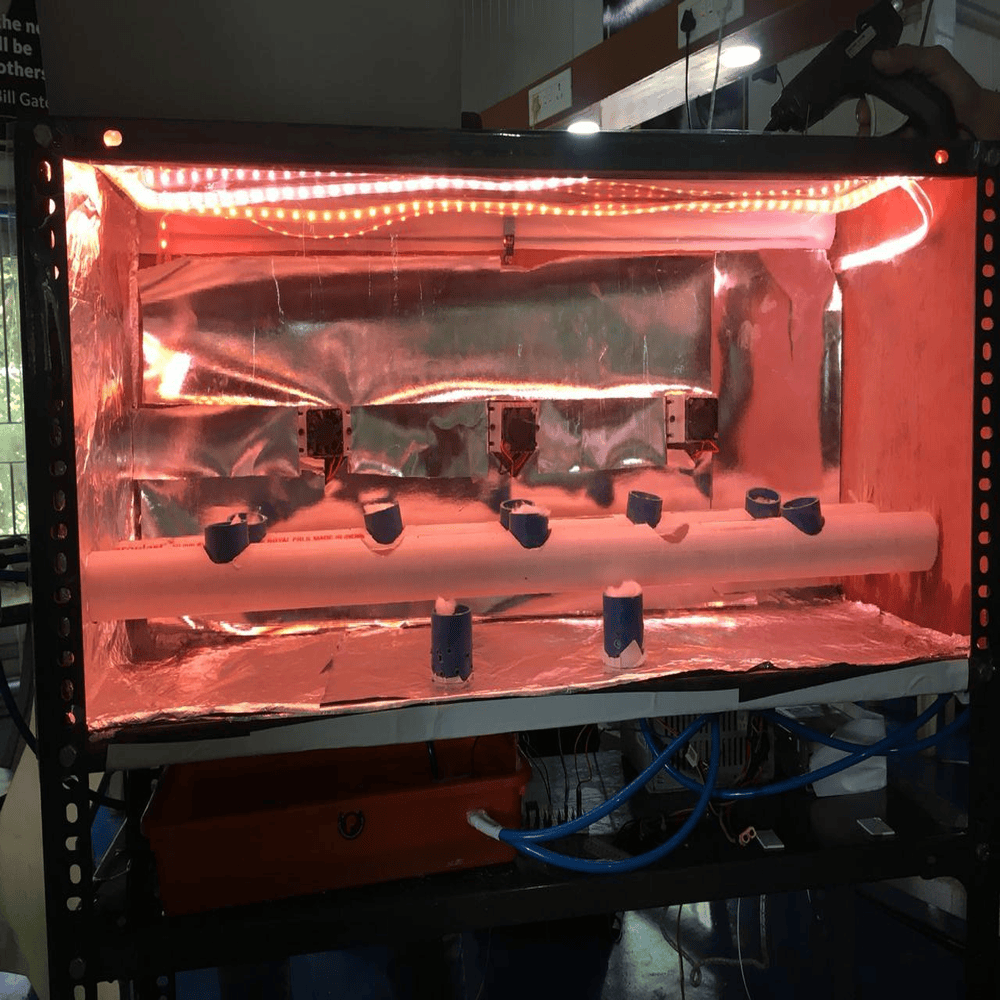

A dedicated a Robotics Engineer with a Master of Science in Mechatronics and Robotics from New York University (NYU). My journey began at SRM Institute of Science and Technology, where I actively contributed to SRM Team Robocon for three years, gaining hands-on experience in robotic system design and integration. Following my undergraduate studies, I joined Honda R&D as a Research Engineer, where I spent two years designing, optimizing and testing vehicle components, collaborating with cross-functional teams, and driving continuous improvement in design and manufacturing workflows. At NYU’s AI4CE Lab, I worked on advanced perception systems, designing and prototyping robust sensor mounts for self-driving platforms. This involved integrating multiple sensors such as LIDARs, GPS-RTK, and cameras—emphasizing structural reliability, vibration dampening, and modularity for real-world data collection. Currently, I am involved in the mechanical development at LevitatePro Inc., building an IoT-based DSLR device. My work focuses on electro-mechanical integration, thermal optimization, and rapid prototyping using SolidWorks and 3D printing—guided by DFM and tolerance analysis for manufacturing readiness. I’m passionate about creating robust, scalable robotic systems that bridge innovation and real-world application. My goal is to contribute to the future of automation and intelligent systems by building reliable, efficient, and human-centric technologies.

Resume